LabelExpress

The LabelExpress laser die cutter is a high-speed label cutting system that delivers high flexibility and great precision with an intuitive operation. With the state of the art CCD module, auto-feed system, waste removal module and re-winder device, as well as an optional slitting module. LabelExpress provides an uninterrupted and unattended workflow on one single compact platform.

Closed-loop DC Servo Technology

A Closed-loop DC servo motor can deliver greater continuous shaft power at higher speeds than a stepper of the same frame size. In addition, It can also give far greater accuracy due to the continuous movement, instead of constant stopping and restarting. GCC high speed closed-loop DC servo motor technology guarantees precise and fast carriage movement with exceptional accurate outputs.

OPTIONS

Auto Sheet Feeder

YDER LabelExpress is now available for sheet to sheet solution, not only for roll media, purchase an add-on sheet to sheet module, you can cut sheet labels or any other sheet application as well. Incorporated with auto sheet feeder, YDER LabelExpress enables users to handle the sheet material from media loading to collecting in a continuous, unattended and efficient manner.

Air Compressor

A specially designed Air Compressor, by using an oil-less diaphragm, you help eliminate the harmful and damaging side effects of moisture on the laser optics. Also, provides the optimal air pressure your laser needs to blow away vaporized particles and helps prevents overheating. A must to keep lenses and mirrors clean to promote longer laser life.

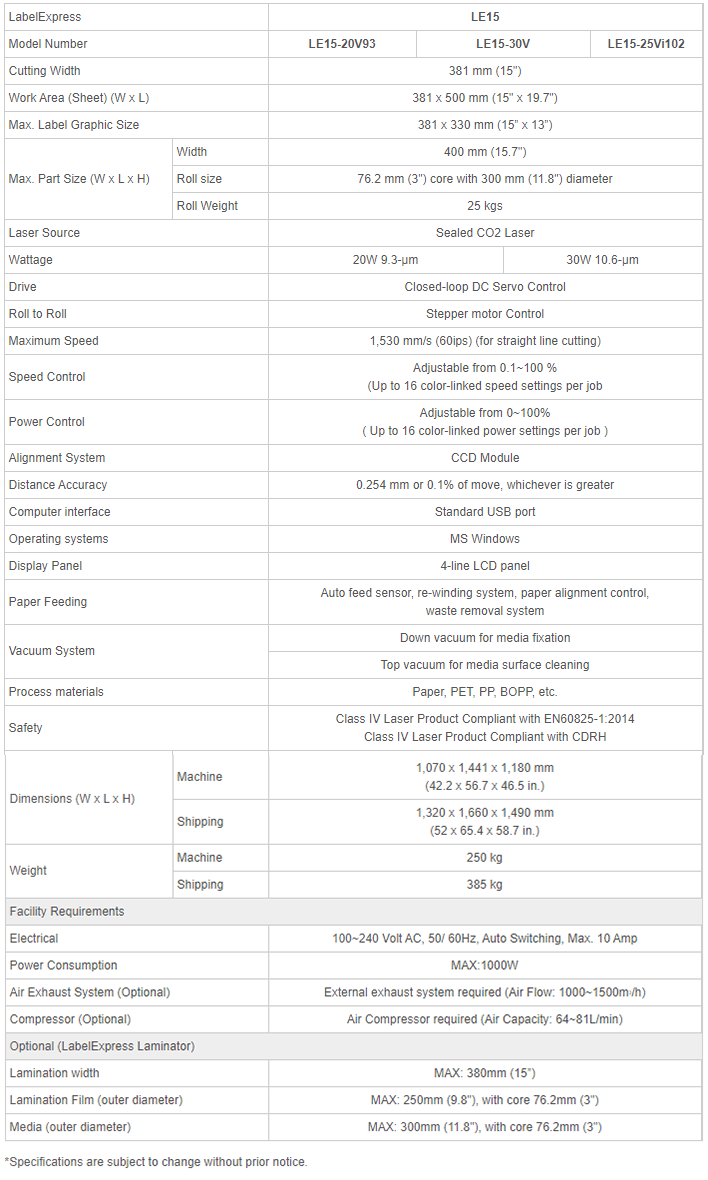

SPECIFICATIONS

www.dccsgi.ca

sales@dccsgi.ca

service@dccsgi.ca